In today’s electronics world, you will probably be working on a project with one or more simultaneous digital components. If you manufacture your own components, it’s good practice to understand what your board is made of, how they work together and what motorization is used to keep the device running smoothly.

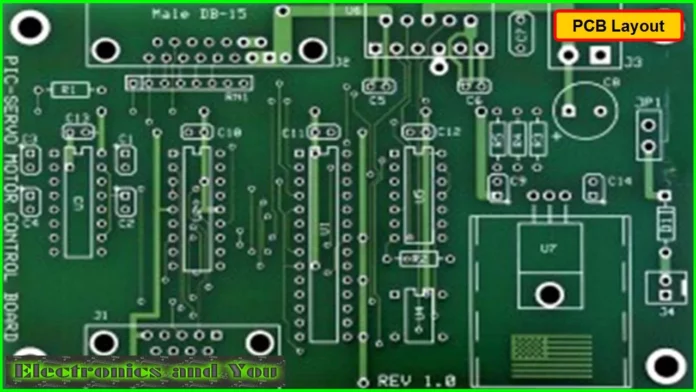

A Printed Circuit Board (PCB) is a network of wires that connect the various electronic components together. The design of a PCB reflects its purpose and its capabilities. It can be used for multiple purposes and it should be designed to last. It doesn’t have to satisfy all your RFID needs; just work with manufacturers like FS Tech that supply parts at an affordable price. Consider these points before producing your first PCB.

What is a Printed Circuit Board?

A Printed Circuit Board (PCB) is a network of wires that connect the various electronic components together. The design of a PCB reflects its purpose and its capabilities. It can be used for multiple purposes and it should be designed to last. It doesn’t have to satisfy all your RFID needs; just work with manufacturers that supply parts at an affordable price.

Consider these points before producing your first PCB. What is a Printed Circuit Board? A Printed Circuit Board (PCB) is a network of wires that connect the various electronic components together. The design of a PCB reflects its purpose and its capabilities. It can be used for multiple purposes and it should be designed to last.

It doesn’t have to satisfy all your RFID needs; just work with manufacturers that supply parts at an affordable price. Consider these points before producing your first PCB.

Why build your own components?

Although it might seem natural to use printed Circuit Board (PCB) designs to connect multiple electronic devices, most manufacturers won’t let you produce a single board without special tools.

You will need to purchase, build and tools up your own PCBs to make use of those tools. You could also purchase pre-built PCBs from vendors like soldering stations, but you will need to buy the parts a little at a time and put them together yourself. Here’s how you build your own PCBs.

How to construct a PCB

The first thing you will do is to cut the traces from your PCB design into smaller pieces. Using a Dremel tool, you will be able to best shape these small traces into larger ones. In order to shape the PCB traces, you will need to use a woodworking tool, like an adze or a planer. To complete this step, you will need at least a table saw and a portable die-cutter.

For your first PCB, you will use a table saw to cut the traces. You will then have the option to use a portable planer to shape these larger traces into smaller ones. Next, you will insert the printed circuit board into the tool and shape it. In this step, you will use a combination of physical and digital tools to create the PCB traces.

For example, you will use a soldering station to join two traces together. Finally, you will use the portable die-cutter to make a final pass through the tool to shape the final PCB trace.

What happens when you produce your first PCB?

First, you will want to ensure that all of the connections on your PCB are made. You will likely need to connect one or all of your devices to the network of GPIO pins on the motherboard. To do this, you will need to connect a cable to the GPIO pin on the board and run it through the cable connection.

You will also need to run a network of wires from the board to the power supply or other speaker or load. Next, you will make your first test circuit. For this, you will need to make several simple circuits with the Soldering Station. This will allow you to connect one trace to the GPIO pin on the board and send data to and from the board.

You will also need to use the trace to attach your device to the network of GPIO pins on the board. Once again, you will need to run a network of wires from the board to the power supply or other speaker or load. Finally, you will attach your components and make sure they are properly seated in the traces on the PCB.

Final Words

In this article, you will learn how to make a Printed Circuit Board (PCB) with today’s greatest tool – the soldering station. This article is targeted towards those who want to make their first PCB and want to start the process of RFID auto-enabling. The soldering station is one of the most versatile tools in the electronics industry.

It can be used to join multiple different parts or it can be used for standalone functions. With the ability to make a single PCB, you can connect multiple devices or components to the network of GPIO pins on the board. You can also use the soldering station to join two or more traces together.

Apart from this, if you want to know about Circuit Protection – Protect Your Domestic Wiring From Power Surges then please visit our Tech category